PMF speaks to Trico’s Senior Brand and Product Manager, Sam Robinson, to discover how motor factors can take advantage of the need for wiper blades in the winter months.

Q. Please could you tell us a little bit about the history of Trico?

Sam Robinson (SR): Trico was the first to manufacture the wiper blade way back in 1917, so with over 100 years’ experience, we like to think we know what we’re doing! We’ve been responsible for some major innovations over the years, from the humble wiper blade itself to wiper motors and washer systems.

Originally founded in the USA, a plant was established in the UK just 10 years later and today, we operate in all continents, with manufacturing, assembly and distribution sites in the USA, South America, Europe, China and Australia. On top of this, in 2019, we acquired the complete wiper blade division of Federal Mogul (Champion).

Q. How does Trico develop new products and technology?

SR: We are constantly working with vehicle manufacturers (VMs) to design and develop new innovations, often on new cars three or four years ahead of their launch. We focus on different areas of improvement to meet their needs, which might include ways that we can improve efficiency on their production line, or ideas to make products lighter to reduce the overall weight of the vehicle.

In Europe, we have our mobile rapid prototyping suite, which allows us to take items for track testing on a vehicle and instantly make tweaks or changes to components in order to improve the performance. Within minutes, we can 3D print new plastic components or stamp new metal parts right there on site and assemble a new blade. This means that a process of maybe three, four or five different blade configurations and tweaks that would have previously taken weeks and months can now be completed in a single day.

Q. How does Trico ensure that its products are of a high quality?

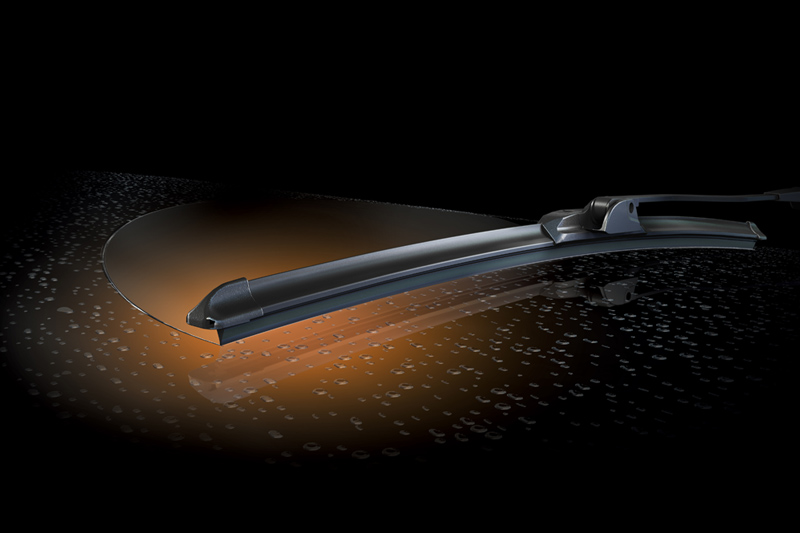

SR: Our products are manufactured and tested to the same specifications as our original equipment (OE) products, using the same components on the same production line. For example, the beam blades we sell in our Exact Fit aftermarket line are the same ones supplied to VMs in their own OES branding. Likewise, our aftermarket Hybrid blade was recently approved for supply to a major VM, and our Force line of high performance blades was created using technology originally developed specifically for one of the world’s most prestigious vehicle brands.

Q. Wiper blades are a seasonal product – how can factors use this to their advantage over the winter period?

SR: Now is the time to be stocking up! In the event of a cold snap, the impact on sales will be instant, and it pays to be ready. Therefore, they should ensure that they have plenty of stock of all types and fitments, and consider promotions on short (multi-clip) ranges to allow workshops to hold a small wall rack or display, so they can quickly and easily change worn wipers when they spot them.

They should also consider some POS material for these workshops, such as posters offering a free wiper blade check, or reminder signs/posters encouraging consumers to replace their wipers every 12 months.

Q. What is the best way to display wiper blades?

SR: Wiper blades remain the ‘forgotten’ product with regard to consumers, as they have no definitive failure point. Having wipers on a large display, room permitting, is great for reminding consumers that they might not have changed their blades recently. Trico recently launched a new 2m wide display that stocks and showcases the full Exact Fit programme of premium direct fit blades, and, so far, this has been a great success with factors and retail stores. In a relatively condensed footprint, it showcases the full range and incorporates prominent signage that highlights their quality and reminds customers to change their wipers once a year.

Q. What are some wiper maintenance tips that factors can offer their customers?

SR: The number one rule at this time of year – don’t start or operate them on a snowy or frozen screen! Starting them this way can completely tear the rubber from the blade, and trying to clear built-up snow or ice can also put undue pressure on the motor, with the catastrophic effect of the complete wiper linkage and/or the motor failing.

Q. Is Trico doing anything to ensure that it is a responsible business, specifically in relation to the environment and waste management?

SR: This is a bigger topic than ever before, and we are currently undergoing a full internal review to identify how we can minimise our environmental impact, in particular with regards to plastic packaging. As an immediate interim measure, we have ensured that all of our plastic packaging is made from recycled and fully recyclable material. However, we recognise that we must look at moving away from plastic altogether, and this is a much larger, ongoing project to identify packaging materials and styles that are more environmentally friendly, whilst still sufficiently protecting the product and providing a striking retail friendly appearance.