Juratek’s Engineering Manager, Bradley Hill, discusses the measures that the company is taking to reduce the harmful particles in friction materials.

A recent report from the parliamentary Air Quality Expert Group detailed that ‘pollution from tyre wear and brake dust contributes to half of the particle pollution from road transport’. It is clear that the action of two surfaces rubbing together, like brake pads on brake discs or tyres on the road, will cause wear to both surfaces.

In the case of brakes, about half of this wear debris is liberated into the air, with some of it dispersed to the roadside, whilst the rest sticks to the wheels of the car and the vehicle body in close proximity to the wheels.

American action

As a result of this, both California and Washington states have imposed regulations to reduce copper and other heavy metals from being present in braking products. The first level of the legislation began in 2014 in California and in 2015 in Washington. All brake manufacturers and importers were required to self-certify that their brake pads contained no more than 0.1% by weight of asbestos, cadmium, chromium, lead, and/or mercury.

On 1st January 2021, the second phase of the legislation will go into effect. This phase will require brake manufacturers and importers to self-certify that their brake pads contain no more than 5% by weight of copper. By 2025, this must be less than 0.5%.

Preparing for European application

Of course, this law does not apply in Europe. However, the principles behind it are to everyone’s benefit; reducing harmful pollution is good for everyone.

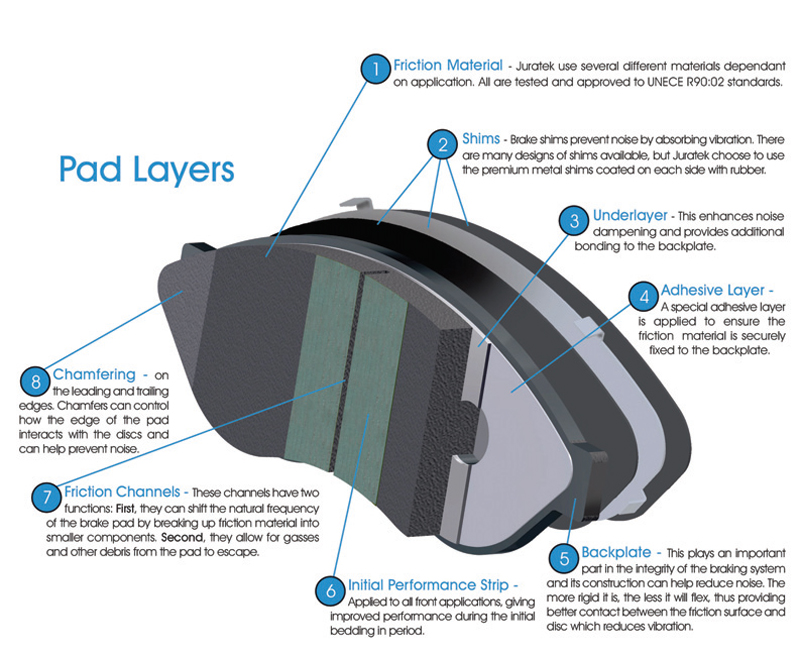

Like others in the industry, Juratek has been rightly concerned about the health hazards that might be posed by brake wear debris, and for some years now, our range of brake pads has been fully environmentally friendly, with all of our pad materials being free from heavy metals and copper. This presented our product development team with a significant challenge – to ensure that the products still had industry-leading standards of performance and freedom from noise and judder, whilst retaining reasonable pad and disc life. In summary, our aim was to ensure Juratek pads provide premium service performance, without costing the earth.

Obviously, governments are looking to go further than just restricting the use of some of the more problematic ingredients of brake pads. It has been established that this wear debris, or particulate matter, which is a mixture of both pad and disc debris, ranges in particle size from > 100 μm to approximately 0.1 μm, with some of it falling in the critical respirable range of 10 μm to 1 μm.

Reducing particle emissions further will require a much broader approach across a number of fronts, so we are seeing special hard coatings being applied to the surface of brake discs to reduce their wear rates, with carbon-ceramic discs offering reduced wear, albeit at a significantly higher cost.

The industry is also exploring partially enclosing brakes and fitting them with filters in order to capture the bulk of the particulate emissions, so it seems likely that the final outcome will be a combination of measures.