febi’s UK Marketing Manager Traci Varley discusses the company’s steering and suspension offering.

Motor factors can be assured that steering and suspension parts from febi comply precisely with the product standards of the respective original equipment suppliers, making us your strong partner in the automotive aftermarket.

febi’s consistent high product quality is assured with comprehensive, repeatedly performed product checks – from initial sample tests through to detailed incoming goods inspections. These test continuously challenge and reconfirm the claim of OE matching quality for every steering and suspension component.

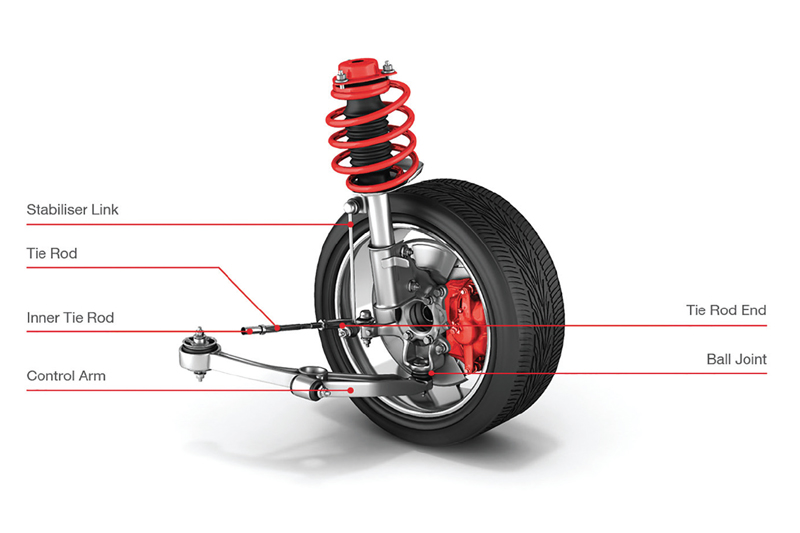

We believe that febi should be a factor’s number one choice, with more than 8,000 steering and suspension articles covering 95% of popular vehicle types, manufactured in OE-matching quality. The comprehensive range includes control arms, tie rods, ball joints, stabiliser links, and much more.

The complete repair solution

Febi also offers a range of steering and suspension ProKits, which are a tailor-made solution for workshops looking to offer a complete repair for their customers. The ProKits are assembly kits that include all the necessary mounting parts (control arm bearings, mounting brackets, spring lock washers, and more), so repairs can be completed without delay. Our claim to have consistent quality of parts across the entire range can be demonstrated with the febi ProKit. The high-quality standards apply to all connecting materials, not just the main wear parts.

Call us to discuss your requirements and see how we can support you. Want quality and value? Choose febi!

Testing spotlight

Our team of steering and suspension specialists subject every sample part to extensive tests in a specially equipped laboratory. Here are some examples:

Control arms: All febi control arms are measured with a 3D scanner. Based on so-called ‘false colour images’, the parts can then be compared with their OE equivalents, with the images making any deviation visible.

Rubber-to-metal: Components such as control arm bearings are checked with the help of a Zwick Roell tensile testing machine. The focus of performance tests includes measuring the stiffness, engagement force and release load.

Welded joints: Welded joints are not only visually inspected, they are also checked for stability, as per DIN ISO 5718, based on cross-sectional views.