Never has the world been so unpredictable, according to European Exhaust & Catalyst (EEC) Commercial Director, Paul Newby, from the global impact of COVID-19 to the situation in Ukraine. Global instabilities have led to spiraling costs, commodity shortages and other challenges that no short-term stratagem can feasibly outweigh, but while paradigms are shifting, Paul says EEC has focused on circumstances it can control:

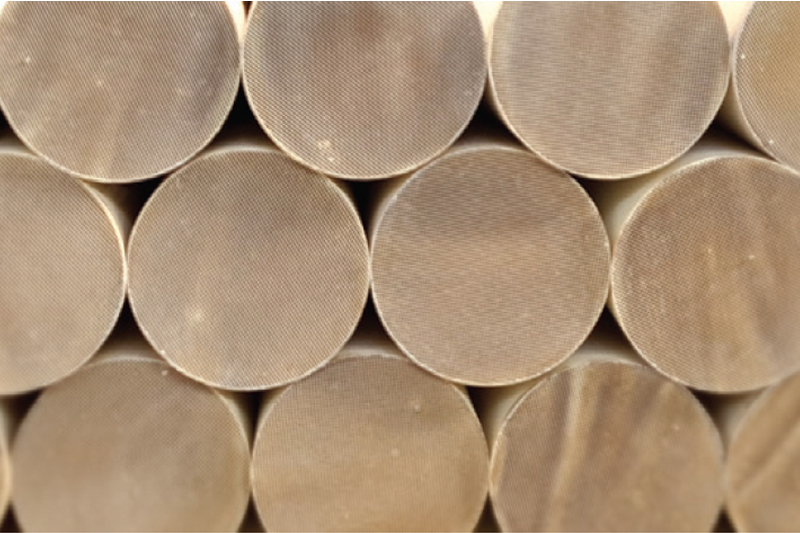

During the pandemic, we worked hard to expand our portfolio of must-have Euro 5 and 6 catalysts, diesel particulate filters and selective catalytic reduction systems, along with a plethora of exhaust and complementary items, enabling us to release more new products than at any time in our 25-year history as a manufacturer.

Over the last couple of years, laboratory capacity for type approval testing has been extremely limited, largely due to the backlog of vehicle manufacturer testing following closures during the pandemic; however, our product development team has managed to navigate us through the roadblocks and successfully completed multiple type approval test phases over the last year or so.

Of course, having desirable, innovative aftermarket products is only one facet of a great customer experience, so we recognised the need to look inwardly and question what we feel makes for an exceptional customer experience and capitalise on what differentiates our company within our peer group.

“Constantly bolstering our knowledge base”

Our customers already speak very highly of our product quality and our aftersales technical support, and our teams all appreciate the importance of sustaining exacting standards. Employee involvement is valued strongly within our company, and all are actively involved in reducing the eight types of waste that we collectively recognise.

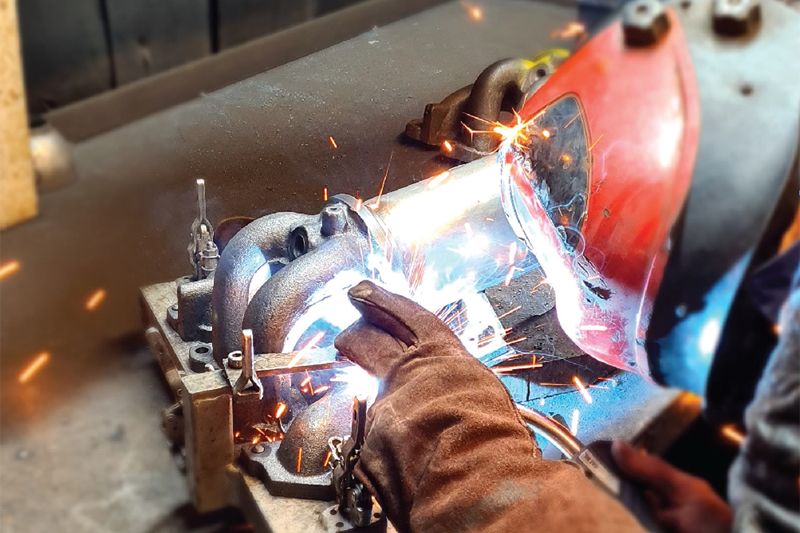

Our manufacturing teams have engaged in activities to improve error-proofing, repeatability and reproducibility, along with enhanced defect detection. With an ever-expanding range, the importance of quick changeover times is paramount; in short, as the number of active parts in range increases, the time we have to produce each batch decreases, so minimising non-value-added activity is crucial. Taking inspiration from pitstops in motorsport, our teams have systematically improved performance in this area.

Our product is technical in nature and customer feedback suggests that our capabilities in relation to technical support and problem resolution are qualities held in high regard. We do not outsource the most technical element of our product, so the unique processes we employ facilitate a deeply intimate comprehension. Despite our technical team being underpinned by decades of experience from within the sector, we appreciate that our expertise must evolve as vehicle technology progresses. We are constantly bolstering our knowledge base to ensure we’re equipped to provide the best possible levels of both technical support and training.

The entire EEC team are proud to walk the talk, and we are more than happy to share our story. If you’re interested in a tour of our facilities, please contact sales@eurocats.co.uk.

![The [M]enable mental health movement explained](https://pmfmag.co.uk/wp-content/uploads/2024/03/Menable-mental-health-165x109.jpg)