Banner discusses how vehicle batteries are now used for so much more than just providing starting power. The company highlights its role in the continued evolution of this technology.

Considering it takes roughly 10,000W to power the average family home, it seems quite staggering that cars require approximately 6,500W of energy per day. If this comes as a surprise, the illustration below pinpoints exactly what the battery is required to power.

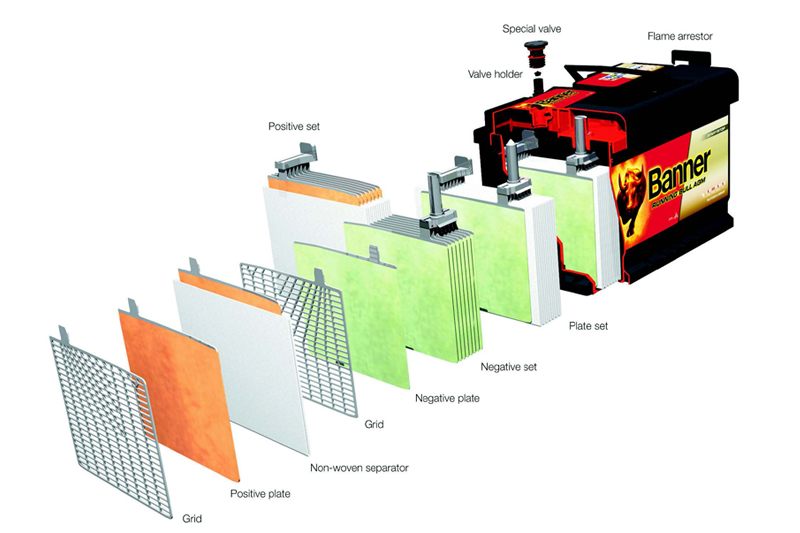

The demand for delivering more power has subsequently resulted in manufacturers developing the current generation of starter batteries that continue to lead the field; EFB (Enhanced Flooded Battery), AGM (Absorbent Glass Mat) and VRLA (Valve Regulated Lead Acid) batteries. Traditional lead acid batteries are still on the scene, although their lifespan is now in increasing jeopardy. Alarmingly, despite having been in existence for a number of years now, there is still some confusion about AGM and EFB batteries in terms of the role that they play and what needs to happen when they are replaced.

Legislation drivers

Firstly, it’s important to remember that these battery technologies are here to stay, and not just because they have the ability to deliver power throughout the vehicle, but because they correspond with the all-important eco-initiatives that governments are implementing to meet EU legislation. The current EU legislation on emission targets was passed in 2009, and it committed vehicle manufacturers to cut the average CO₂ emissions from new vehicles to 130g/km by 2015 and 95g/km by 2020. Legislation discussions have stated that figures of up to 250€/gram of CO₂/km may be charged based on the manufacturer’s average fleet emissions, which exceed the legislative level for the time period between emission reduction targets. This charge will be applied to every vehicle sold by that manufacturer.

It is against this backdrop that OE battery manufacturers continue to work closely with vehicle producers to deliver power solutions that not only exceed automotive power output requirements, but which are also emission friendly. In order to deliver on these two fronts, OE battery manufacturers have to produce a solution that is designed and produced to exceed a normal life expectancy. This means using only the highest quality components, as opposed to producing on price alone.

Advanced eco-initiatives

So, let’s not forget that OE manufactured batteries of the EFB and AGM type are proven to perform both on the car and in favour of the environment. But the story isn’t about to end there. With more dynamic eco-initiatives being developed, again to help drivers save fuel and reduce vehicle CO₂ emissions, it’s increasingly important to keep deploying the highest quality battery technology.

So, let’s not forget that OE manufactured batteries of the EFB and AGM type are proven to perform both on the car and in favour of the environment. But the story isn’t about to end there. With more dynamic eco-initiatives being developed, again to help drivers save fuel and reduce vehicle CO₂ emissions, it’s increasingly important to keep deploying the highest quality battery technology.

Recent eco-initiatives centre on tyre pressure monitoring systems (TPMS), low-rolling resistance tyres, gearshift indicators, and new radical technologies, including electronic camshafts or electronic valve timing systems that allow the engine tune to be optimised to driving style.

Despite not impacting the automotive aftermarket, when it comes to AGM and EFB batteries, these technologies are here to stay. Isn’t it then wise to start now, if you haven’t already, by adopting a philosophy of stocking and recommending a battery solution that is capable of delivering power to the entire vehicle?

![The [M]enable mental health movement explained](https://pmfmag.co.uk/wp-content/uploads/2024/03/Menable-mental-health-165x109.jpg)