Replacement and remanufactured components are often seen as lesser than their OE counterparts. Adam Griffiths, Brake Engineering’s UK Marketing Lead, takes PMF through the company’s remanufactured braking solutions and their place in the aftermarket.

Q: What are the opportunities and barriers to remain in your sector?

Adam Griffiths (AG): Education is key. With such a safety-critical product group like braking, it’s essential that the quality is consistent through a supply chain that offers full traceability and support to distributors and workshops.

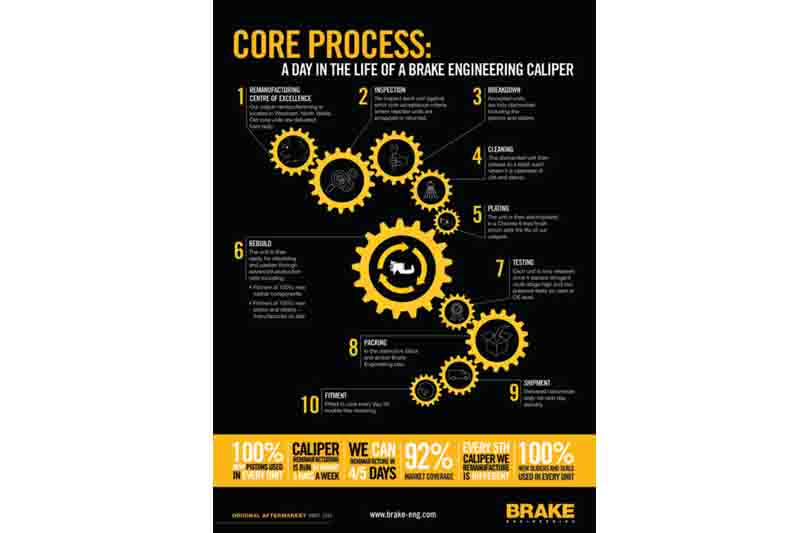

We have a ‘Day in the life of a brake engineering caliper’ poster available to our customers, and this is designed to demonstrate our thorough approach to remanufacturing, which takes place at our Wrexham-based facility 24 hours a day, five days a week.

All wearing parts are replaced with brand new components, and the caliper housing is given a corrosion resistant, zinc plated finish that abides by current EU legislation. The caliper is then pressure tested to strict quality guidelines, with batch marking being used for essential traceability.

To assist us with the process of collecting core, the Brake Engineering core poster details our stringent acceptance criteria and how we analyse each unit to ensure that it’s fit for remanufacturing.

We are taking steps wherever possible to highlight the quality of our range to customers, and to support them with taking the message further. We have found a demand for quality and support from independent garages, so it’s important that distributors meet these expectations with a product range that is backed-up with technical expertise and parts traceability.

Q: Why has ‘Original Aftermarket’ struck such a chord with motor factors?

AG: ‘Original Aftermarket’ distinguishes Brake Engineering’s position in the marketplace. The term is used as a message to customers to promote transparency in areas such as product quality, technical support and customer service, and comes from extensive market research undertaken by Brake Engineering in the automotive industry.

This research was designed to determine what customers expect from a supplier in terms of service, range, availability, reliability and support. From the results and subsequent analysis, the term has become a positioning statement for the brand, and demonstrates the level of added value service that sets the brand apart.

Original Aftermarket proudly states that we are an aftermarket brand that is in complete control of the manufacturing process. We remanufacture brake calipers to the highest possible quality and add them to our range. It is this attention to detail that is driving demand for our products from customers.

Original Aftermarket encompasses all we have to offer, and lays bare our unrivalled dedication to the automotive aftermarket, with range development, customer service, stock profiling and marketing four of our methods of demonstrating our commitment to aftermarket businesses.

We want motor factors and garages to buy in to Brake Engineering’s full line braking parts solution. For over 30 years, the Brake Engineering brand has been a prominent part of the supply of remanufactured brake calipers. This is in response to calls from technicians that want to fit the full range of Brake Engineering products to ensure the correct fitment of parts, compatibility, and to receive the very best technical support.