As engine temperatures rise, so too has the market for exhaust gas temperature sensors. Delphi Technologies believes it can help factors and their customers access a growing business stream.

In an effort to meet ever-tightening emissions legislation, today’s downsized engines are smaller, cleaner and more fuel-efficient than their larger predecessors, yet thanks to direct injection, turbocharging and supercharging, they deliver as much power, if not more.

The downside is that modern engines have to work much harder, generating higher combustion pressures and temperatures. This makes them and their systems more vulnerable to durability issues unless they are adequately protected. In the front line of this protection is the exhaust gas temperature (EGT) sensor.

Originally designed to monitor the catalytic converter, EGT sensor technology has become more and more complex in recent years. Now, its main job is to protect key components from high temperatures in both diesel and petrol engines. So, if the sensor detects too much heat, the ECU will step in and take appropriate action to reduce it. For example, by lowering boost pressure in the case of the turbocharger, or by increasing the quantity of fuel injected in a naturally aspirated engine, to protect the catalytic converter. In diesel engines, they are also used to monitor the temperature of the diesel particulate filter (DPF) to identify the correct time for DPF regeneration, making them a crucial part of any modern vehicle.

“The rapid growth in the use of EGT sensors creates a good business opportunity for both factors and garages,” said Julian Goulding, UK Marketing Manager. “With three or more of these highly stressed parts fitted to many of today’s vehicles, your customers are likely to be seeing a steady stream passing through their workshop, for which they’ll need an OE-quality replacement at a competitive price point. To help the aftermarket take advantage of this fast-growing opportunity, we’ve recently added EGT sensors to our extensive vehicle electronics line-up.”

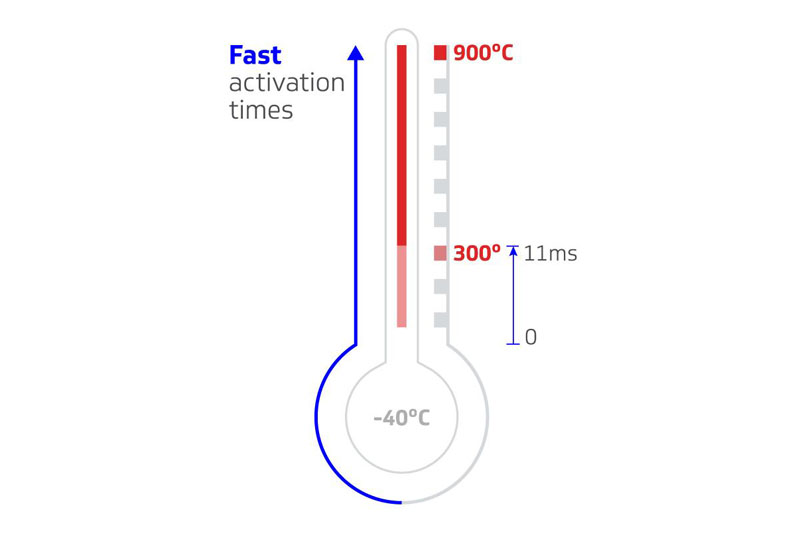

Featuring the latest generation thin film RTDs, Delphi Technologies claims that its EGT sensors provide greater protection from environmental and mechanical stresses, whilst offering improved response times (taking less than 11 milliseconds to jump 300°C) and a wide temperature range (from as low as -40°C, all the way up to 900°C). The new range includes more than 55 parts, covering an extensive vehicle parc with over 480 applications (make/model/engine size), including Audi A3, Volkswagen Golf and Vauxhall/Opel Astra.

Julain continued, “As the trend for downsizing continues, engine temperatures will get even hotter, and so will the aftermarket opportunities. By always recommending a quality EGT sensor from an OE engine management provider like Delphi Technologies, you and your customers can make the most of this fast-growing market, generating additional revenue and profitability.”

Evolving with vehicle advancements

As vehicles and automotive engineering have evolved, Delphi Technologies claims that its drive to provide the aftermarket with the parts required to maintain a vehicle parc that is brimming with new technology has also shot through the roof.

The creation and continued enhancement of its EGTS line-up illustrates its commitment to the industry in providing the required parts in a timeframe that suits the aftermarket, whilst ensuring that they are a first-time fix that conforms to OE specification.

Delphi regards its EGTS line-up as one of the most complete and extensive available, spanning in the region of 6,600 applications. Tested for durability, performance and environmental compliance, the sensors offer many benefits, such as consistent output throughout a broad temperature range, accurate temperature detection and a closed tip design that is highly resistant to heat, vibration and contamination.

As an example, the company’s latest generation of sensors are said to be able to measure precise temperatures from as low as -40°C, all the way up to 900°C – taking less than 11 milliseconds to jump 300°C. Such fast and accurate measurement in rapidly changing conditions is essential in optimising engine performance and efficiency.

![The [M]enable mental health movement explained](https://pmfmag.co.uk/wp-content/uploads/2024/03/Menable-mental-health-165x109.jpg)