A quality business management solution can help factors stock the most appropriate inventory all year round. MAM Software explains how.

Seasonal demand has a significant impact on motor factors and accessory retailers. Being able meet demand for certain products at different times of the year is crucial.

Without managing seasonal inventory accurately, businesses risk stock shortage or surplus. If a company has insufficient stock to meet demand, it risks upsetting customers or incurring additional expense – either costly replacements need to be sourced, or there’s a danger customers will look elsewhere. On the other hand, surplus stock results in unnecessary expenditure and incurs additional storage and administration costs.

In order to successfully meet the fluctuating demand of their customers, aftermarket companies need to manage and adapt their stock levels efficiently. Thankfully, modern business management solutions provide business owners with tools that allow them to meet the challenges of changing levels of demand throughout the year.

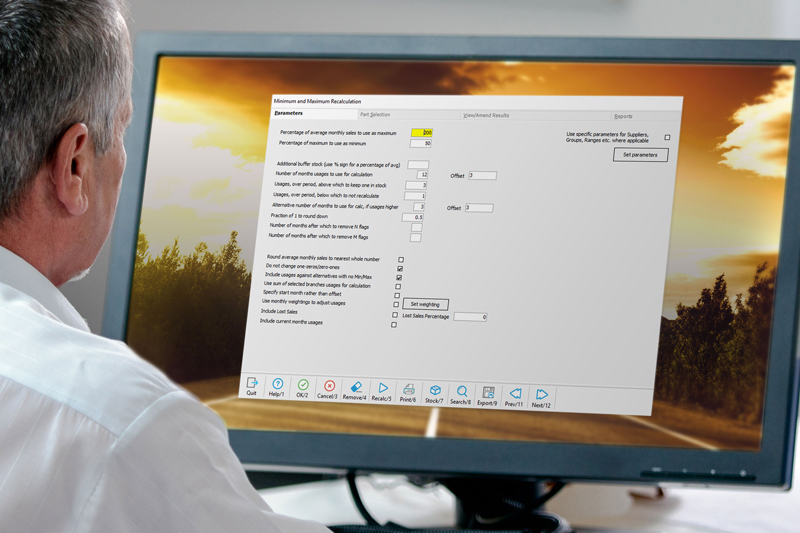

MAM’s Autopart management software provides routines to recalculate minimum and maximum stock levels based on monthly usage. While this will happily cater for incremental shifts, such as changes to the vehicle parc, managing annual fluctuations often requires further analysis.

To accurately identify seasonal trends, Autopart allows usage calculations to be offset, so stock levels are compared against a previous period. For example, rather than calculating stock levels based on the last three months’ usage, it can compare the same period from the previous year.

Furthermore, the software provides a weighting system to inflate or deflate stock level calculations. If a product sells well in one particular period, stock levels can be inflated in subsequent periods to meet the growing demand. This enables business owners to adapt reorder levels in line with sales trends. In addition, if a company is losing business because items are out of stock, these ‘lost sales’ can be taken into consideration when recalculating stock levels.

Of course, seasonal demand will vary on a product-by-product basis. For example, items such as batteries, antifreeze, screenwash and wiper blades typically have higher demand during the winter months. Autopart allows users to adjust reorder calculations on a product, group, range or classification basis, ensuring that items are appropriately stocked throughout the year. It also provides reports to establish the change in stock value and the cost to restock to new levels.

Autopart also provides ordering routines that enable users to respond instantly to changes in demand, which is extremely useful given the unpredictable nature of the British weather. Some features, such as electronic ordering from suppliers or warehouse distributors, shorten response times. Non-stocked items can be easily ordered and sold, and converted to stocked items if required. Alternatively, one-off sales can be flagged as ‘exceptional’, so that stock is not replenished when it expires.

Combined, these features help ensure that motor factors and accessory retailers are prepared to meet demand as the seasons change. Holding the right stock at the right time is fundamental to the aftermarket, and MAM’s Autopart provides the tools business owner’s need to make sure the most appropriate inventory is stocked all year round.